Best Selling Products

3D Technology: Explore Industry Trends and Innovations

Nội dung

- 1. Overview of 3D technology in the 21st century

- 1.1. Concept of 3D technology and scope of application

- 1.2. Development history and notable milestones

- 2. Current prominent 3D technology trends

- 2.1. The rise of 3D printing in industrial manufacturing

- 2.2. The future of product design with 3D simulation

- 2.3. 3D in media, entertainment and film

- 3. Innovation in industries using 3D technology

- 3.1. Precision medicine thanks to 3D printing technology

- 3.2. Digital architecture and construction thanks to 3D modeling

- 3.3. Fashion, art and interior design

- 4. Integrating 3D technology with AI, VR and AR

- 4.1. Expand your creativity with AI-powered rendering

- 4.2. Virtual and augmented reality in 3D environments

- 5. Challenges and opportunities when applying 3D technology

- 5.1. Technical barriers and equipment investment

- 5.2. Career opportunities and 3D human resource training

- 6. Innovation in manufacturing with 3D technology

- 6.1 3D printing in industrial production

- 6.2 Optimizing product design

- 6.3 Accelerate the testing process

- 7. Applications in medicine and health care

- 7.1 Bioprinting and Artificial Organs

- 7.3 Customized medical devices

- 7.4 Digital dentistry

- 8. 3D technology in construction and architecture

- 8.1 3D printing of houses and civil works

- 8.2 Freedom of design and space optimization

- 9. The Future of 3D Technology: Merging with AI and IoT

- 9.1 Incorporating AI to optimize design and printing processes

- 9.2 Internet of Things (IoT) and smart printing lines

- 9.3. Current barriers and challenges

- 10. Conclusion

Explore the pivotal role 3D technology plays in modern industries. From 3D printing, digital simulation to visual design, this article analyzes the trends, innovations and outstanding potential of this technology.

3D technology is playing an important role in reshaping a wide range of fields, from product design, healthcare to architecture and communications. Improvements in 3D printing, digital simulation, visual design and real-time rendering not only increase productivity but also open up unprecedented creative spaces. In the digital age, the development of 3D is not just an option but has become an inevitable direction. Update detailed information below at sadesign.vn !

1. Overview of 3D technology in the 21st century

3D technology in the 21st century has become one of the pioneering trends, bringing significant breakthroughs in many fields such as medicine, architecture, manufacturing, entertainment and education.

.jpg)

1.1. Concept of 3D technology and scope of application

3D technology refers to the process of creating and manipulating three-dimensional objects through specialized software and advanced hardware. 3D images or models can be built, printed, or displayed through virtual environments to simulate real-world spaces.

The application of 3D has spread to almost every field: medicine, construction, architecture, automotive industry, aviation, video games, cinema and education. Key technologies such as 3D printing, virtual reality (VR), augmented reality (AR) and 3D modeling are all driving a wave of continuous innovation.

1.2. Development history and notable milestones

The birth of 3D technology began in the late 20th century, associated with computer graphics software such as AutoCAD, Maya or 3ds Max. From being used only in the entertainment and architecture industries, 3D technology quickly exploded thanks to its ability to create surreal images and superior production efficiency.

2009 marked a major turning point when 3D printing technology became more widely popular, opening the trend of personalized and material-saving production. The birth of cheap 3D printers also created conditions for many individuals and small businesses to participate in this market.

2. Current prominent 3D technology trends

The current 3D technology trend is becoming one of the rapidly developing fields, bringing many potential applications in different industries.

2.1. The rise of 3D printing in industrial manufacturing

3D printing (Additive Manufacturing) is no longer a science fiction technology. In fact, major manufacturers are using 3D printing to create aircraft parts, automotive accessories, architectural models, and even building materials. The obvious advantages are high customization, cost savings in production, and reduced material waste.

.jpg)

One of the notable innovations is the application of biomaterials in 3D printing to create artificial body parts, contributing to a major step forward in regenerative medicine.

2.2. The future of product design with 3D simulation

3D simulation software such as SolidWorks, Rhino or Fusion 360 are helping designers test the feasibility of products right from the sketching stage. Product development processes can now be shortened thanks to the ability to visualize each part in digital form, helping to speed up testing and reduce errors.

Digital twin simulation models are also becoming a leading trend, allowing real-life product monitoring and analysis through virtual copies.

2.3. 3D in media, entertainment and film

Blockbuster movies, video games, and commercials today all use 3D rendering technology to create vivid and emotional frames. Combining 3D rendering technology with AI has expanded the possibilities for creating content, from virtual characters to entire digital worlds.

Many studios are integrating real-time rendering into their production workflows to increase creative efficiency, reduce post-production time, and allow for instant previews of the finished product as it is edited.

3. Innovation in industries using 3D technology

In the entertainment industry, 3D technology is changing the way movies and video games are produced. It brings a more vivid and realistic experience to users.

3.1. Precision medicine thanks to 3D printing technology

In modern medicine, 3D models are being used to simulate anatomy, plan surgeries, and train medical students. In particular, 3D printing technology has facilitated the production of biocompatible prosthetics, exoskeletons, or soft tissues that are tailored to each patient.

Additionally, bioprinting research holds promise for creating human organ models for transplants or drug testing.

3.2. Digital architecture and construction thanks to 3D modeling

Construction and architectural firms today use 3D integrated BIM (Building Information Modeling) software to manage projects, design buildings and control costs. This technology not only helps predict risks but also optimizes materials and increases construction accuracy.

Some pioneering companies have applied construction robots combined with 3D drawings to build houses in a shorter time and more safely.

3.3. Fashion, art and interior design

The creative industry is also taking full advantage of 3D to innovate workflows. In fashion, designers can build virtual outfits on 3D human models to showcase products without having to physically manufacture them.

Similarly, interior designers are using 3D technology to create perspectives, test materials, lighting and space layouts visually and vividly before actual implementation.

4. Integrating 3D technology with AI, VR and AR

The integration of 3D technology with artificial intelligence (AI), virtual reality (VR) and augmented reality (AR) is opening up breakthrough opportunities in many fields such as:

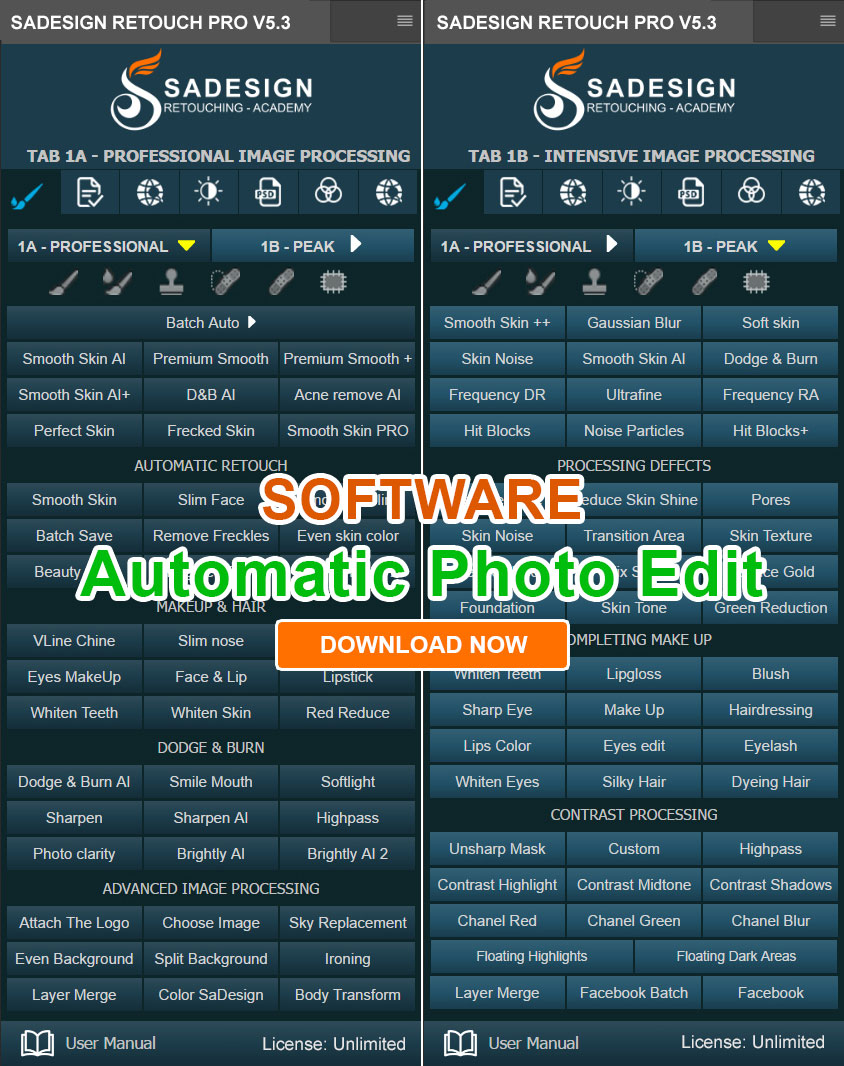

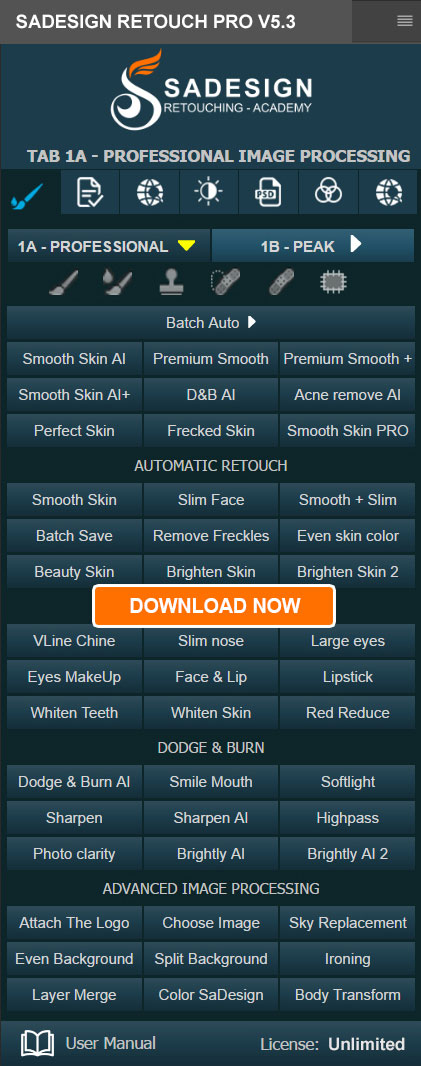

4.1. Expand your creativity with AI-powered rendering

The combination of artificial intelligence and 3D technology is bringing about a huge leap in creativity. AI can now support automatic modeling, mesh optimization, lighting and materials based on a predefined style.

.jpg)

Tools like Blender, Unity, Unreal Engine have integrated AI plugins to save time and speed up the process of producing 3D content.

4.2. Virtual and augmented reality in 3D environments

Virtual reality (VR) and augmented reality (AR) are two key factors when it comes to 3D in user experience. In training, education or exhibitions, VR allows creating a completely virtual learning environment, helping to increase learning efficiency.

On the contrary, AR is strongly applied in e-commerce and marketing, allowing users to experience products directly through smartphones without actual contact.

5. Challenges and opportunities when applying 3D technology

The application of 3D technology in various fields brings many development opportunities but also poses many challenges.

5.1. Technical barriers and equipment investment

Despite its many advantages, 3D technology still requires a large initial investment cost, both in software and hardware. In addition, the requirement for skilled human resources is also an obstacle for small businesses.

Asynchronous file formats, complex rendering processes, and long render times are also issues that need to be optimized in the future.

5.2. Career opportunities and 3D human resource training

Along with the challenges, a series of new career opportunities are being created. Positions such as 3D artist, motion designer, game designer, 3D engineer or simulation architect are all in strong demand.

Many universities, training centers and online courses have quickly included content on 3D modeling, AI and simulation technology in their programs to meet market demand.

6. Innovation in manufacturing with 3D technology

6.1 3D printing in industrial production

No longer limited to the prototype stage, 3D printing has now penetrated deeply into mass production. Companies that manufacture spare parts, medical devices, automobiles and aviation have applied 3D printing to create high-precision parts, reduce waste materials and optimize the supply chain.

The aerospace industry in particular has benefited significantly from this technology. Complex parts that traditionally required multiple machining steps can now be produced in a single print run. This not only reduces production time but also reduces component weight – a key factor in this industry.

6.2 Optimizing product design

A notable strength of 3D technology is the ability to optimize designs through simulation and proofing. Before a product goes into mass production, designers can print prototypes and make multiple adjustments based on feedback from the engineering team or target consumers. This flexibility increases investment efficiency and reduces the risk of defective or unsuitable products for the market.

6.3 Accelerate the testing process

Traditionally, a product development cycle can last for months or even years. With 3D printing, this time is significantly shortened thanks to rapid prototyping. Businesses can launch a test version in just a few days to promptly adjust or reach customers early, creating a significant competitive advantage.

7. Applications in medicine and health care

7.1 Bioprinting and Artificial Organs

3D bioprinting technology is opening up new directions in the field of regenerative medicine. Thanks to the ability to use "bio-inks" - usually living cells combined with compatible biomaterials - scientists can print soft tissues such as skin, cartilage and even liver, kidney or heart structures.

Although still in the research stage, printing artificial organs promises to completely change the organ transplant system, reducing the shortage of donated organs and limiting the risk of organ rejection.

7.3 Customized medical devices

From prosthetic limbs to medical aids such as braces, catheters and implants, 3D printing enables the production of highly precise and custom-made medical devices for each patient. By scanning the body and designing a suitable model, patients not only receive more effective devices but also save treatment and recovery time.

7.4 Digital dentistry

The dental industry is one of the first to benefit from 3D technology. The creation of dentures, clear aligners, crowns and dentures is now faster, more precise and more cost-effective than traditional techniques. In particular, CAD/CAM software integrated with 3D printing makes the treatment process smoother, more aesthetic and less error-prone.

8. 3D technology in construction and architecture

8.1 3D printing of houses and civil works

One of the most daring innovations is 3D printing an entire house or architectural structure. With 3D concrete printing technology, construction units can complete a level 4 house in just a few days. This technology helps reduce labor, limit construction waste and is especially useful in disaster areas that need temporary housing.

Many countries have successfully tested this model in building social housing, flood-proof houses, desert houses or public works such as bridges, benches, and electricity booths.

8.2 Freedom of design and space optimization

Architects are no longer limited by old stereotypes. 3D technology allows the design of complex structures, unique curves and shapes that go beyond the limits of traditional materials. This creates a new trend in modern architecture: creative, sustainable and personalized.

9. The Future of 3D Technology: Merging with AI and IoT

.jpg)

9.1 Incorporating AI to optimize design and printing processes

Artificial intelligence is helping to improve the efficiency of 3D printing by analyzing production data, predicting printing errors, and suggesting model modifications. AI algorithms can learn from previous prints to optimize print paths, reduce waste material, and ensure the quality of the final product.

In product design, AI is also integrated to create new geometric forms using the "generative design" method - where the computer proposes hundreds of structural options based on input functional requirements.

9.2 Internet of Things (IoT) and smart printing lines

In smart factories, 3D printers will no longer operate independently but will become part of a production chain connected via IoT. Printers will receive commands automatically, monitor performance remotely, automatically check for errors, and send feedback data to the control center. From there, businesses can monitor the entire process and optimize every step from raw materials to distribution.

9.3. Current barriers and challenges

Copyright and 3D data security issues

The development of 3D printing also brings with it concerns about copyright infringement when design models are copied or distributed illegally. This raises the need for a clear legal corridor for intellectual property rights in a highly digital environment.

Additionally, 3D model files – especially in the medical and defense sectors – can have serious consequences if they are hacked or modified by hackers. Therefore, data security becomes a top priority when developing networked 3D printing systems.

Material and technology costs

Although manufacturing costs have dropped significantly, specialized materials such as high-grade metals, carbon fiber, or biomaterials remain expensive. At the same time, the initial investment in large industrial printers and specialized design software also makes many small businesses hesitant to invest.

10. Conclusion

The development of 3D technology not only contributes to productivity but also opens up many new possibilities in terms of creativity, message transmission and realistic simulation. In the context of the world rapidly shifting to the digital economy, 3D is no longer an option but has become a mandatory requirement to adapt and lead.