Best Selling Products

Explore Autodesk Fusion 360: Comprehensive 3D Design Software

Nội dung

- 1. Introduction to Autodesk Fusion 360

- 2. Key features of Autodesk Fusion 360

- 2.1 3D Design and Modeling

- 2.2 CAM machining and 3D printing

- 2.3 Modeling and Rendering

- 2.4 Simulation and analysis

- 2.5 Assembly and movement

- 2.6 Collaboration and data management

- 3. Tools and utilities to support design

- 3.1 Sketching Tools

- 3.2 Parametric Design

- 3.3 CAM (Computer-Aided Manufacturing) machining tools

- 3.4 Simulation and Analysis

- 3.5 Data Import and Export

- 3.6 Rendering tools

- 4. Fusion 360 Beginner's Guide

- 5. Where should I upgrade Autodesk Fusion 360?

- 6. Conclusion

In the era of Industry 4.0, product design and simulation have become easier and more efficient than ever thanks to the advent of 3D design software. Autodesk Fusion 360 is one of the outstanding tools in this field, providing users with a comprehensive platform for product design, simulation and manufacturing. With integrated features from CAD, CAM to CAE, Fusion 360 not only helps engineers and designers save time but also improves accuracy and creativity in the product development process. In this article, Sadesign will join you to learn more about the outstanding features, benefits and practical applications of Autodesk Fusion 360.

In the era of Industry 4.0, product design and simulation have become easier and more efficient than ever thanks to the advent of 3D design software. Autodesk Fusion 360 is one of the outstanding tools in this field, providing users with a comprehensive platform for product design, simulation and manufacturing. With integrated features from CAD, CAM to CAE, Fusion 360 not only helps engineers and designers save time but also improves accuracy and creativity in the product development process. In this article, Sadesign will join you to learn more about the outstanding features, benefits and practical applications of Autodesk Fusion 360.

1. Introduction to Autodesk Fusion 360

Autodesk Fusion 360 is a comprehensive 3D design software that stands out in the industry for its ability to integrate many useful tools for the product development process. Developed by Autodesk, Fusion 360 is not only a CAD tool, but also combines CAM and CAE functions, creating a powerful platform for designers, engineers and manufacturers. From concept to finished product, this software helps users create detailed designs with high accuracy.

One of the highlights of Fusion 360 is its simulation capabilities. The software allows users to test mechanical and physical factors such as stress, temperature, and material strength before actual manufacturing. This not only saves time and costs but also reduces risks in the product development process. In addition, with its realistic 3D design and modeling features, Fusion 360 helps users create realistic 3D models by applying materials from a diverse library, from wood and metal to plastic and glass.

Fusion 360 also excels at facilitating collaboration between team members. Thanks to its cloud-based project management features, users can easily share and synchronize changes in real time. This not only enhances productivity but also ensures that every idea and feedback is captured and acted upon promptly. With a free version for personal and educational use, Fusion 360 is an ideal choice for both beginners and small to medium-sized manufacturing businesses, helping to optimize the design and manufacturing process.

.png)

2. Key features of Autodesk Fusion 360

2.1 3D Design and Modeling

Autodesk Fusion 360 offers superior 3D design and modeling capabilities, allowing users to create solid models, parametric models, and freeform rendering. This feature is especially useful for those who want to express their creative ideas accurately and easily. With T-Splines technology, users can create smooth and complex surfaces, helping to turn abstract ideas into reality.

What makes Fusion 360 stand out is its flexible editing capabilities. Users can change any detail in a model with just a few clicks, saving time and effort during the design process. From creating basic shapes to complex designs, Fusion 360 can meet the needs of both beginners and industry experts.

2.2 CAM machining and 3D printing

Fusion 360 offers a powerful CAM toolkit that supports 2- to 5-axis CNC machining. This feature allows users to create precise tool paths, optimizing machining performance for mechanical parts. Thanks to flexible adjustment capabilities, users can easily customize the machining process to suit specific materials and production requirements.

In addition, Fusion 360 also supports model preparation for 3D printing, including support structure adjustment and print mesh preview. This helps users move from design to production with more confidence, minimizing risk and optimizing the 3D printing process. With Fusion 360, bringing creative ideas to life is easier and more efficient than ever.

2.3 Modeling and Rendering

One of the standout features of Fusion 360 is its modeling and rendering capabilities, allowing users to create realistic images down to the smallest detail. With ray-tracing technology, the software provides sophisticated lighting and shadow manipulation, making your product more vivid and attractive. Users can choose from a rich material library and adjust lighting settings to highlight every aspect of the model.

This feature is not only useful for presenting products to customers, but also helps users evaluate and improve their designs. Creating realistic images enhances communication within teams and makes a strong impression in meetings or presentations.

.png)

2.4 Simulation and analysis

Fusion 360 goes beyond design and offers powerful simulation and analysis capabilities. Users can perform force, temperature, and load simulation tests to evaluate product durability and performance before they go into production. This not only saves time but also reduces risk during product development.

This simulation feature helps users identify potential problems early and make necessary adjustments, thereby optimizing the design. A better understanding of how the product will perform in real-world conditions helps improve the quality and reliability of the final product.

2.5 Assembly and movement

Fusion 360 also offers assembly and motion creation capabilities, allowing users to combine parts to form a complete assembly. This feature not only helps test the interactions between parts but also helps set up kinematic joints to simulate kinematics. Users can easily test how parts work together, detecting and fixing issues before production.

This is especially important in complex projects where the accuracy and performance of each component greatly affects the entire product. Fusion 360 helps users perform dynamic testing easily and efficiently, thereby improving product reliability when it comes to market.

2.6 Collaboration and data management

One of the big advantages of Fusion 360 is its ability to support collaboration and data management. With the cloud platform, users can easily store, share, and manage projects in real time. This allows team members to work together effectively, track versions, and feedback easily.

This feature not only enhances communication between team members but also ensures that all changes are recorded and updated in a timely manner. Thanks to its intelligent data management capabilities, Fusion 360 helps users save time and improve work efficiency, thereby optimizing the product development process.

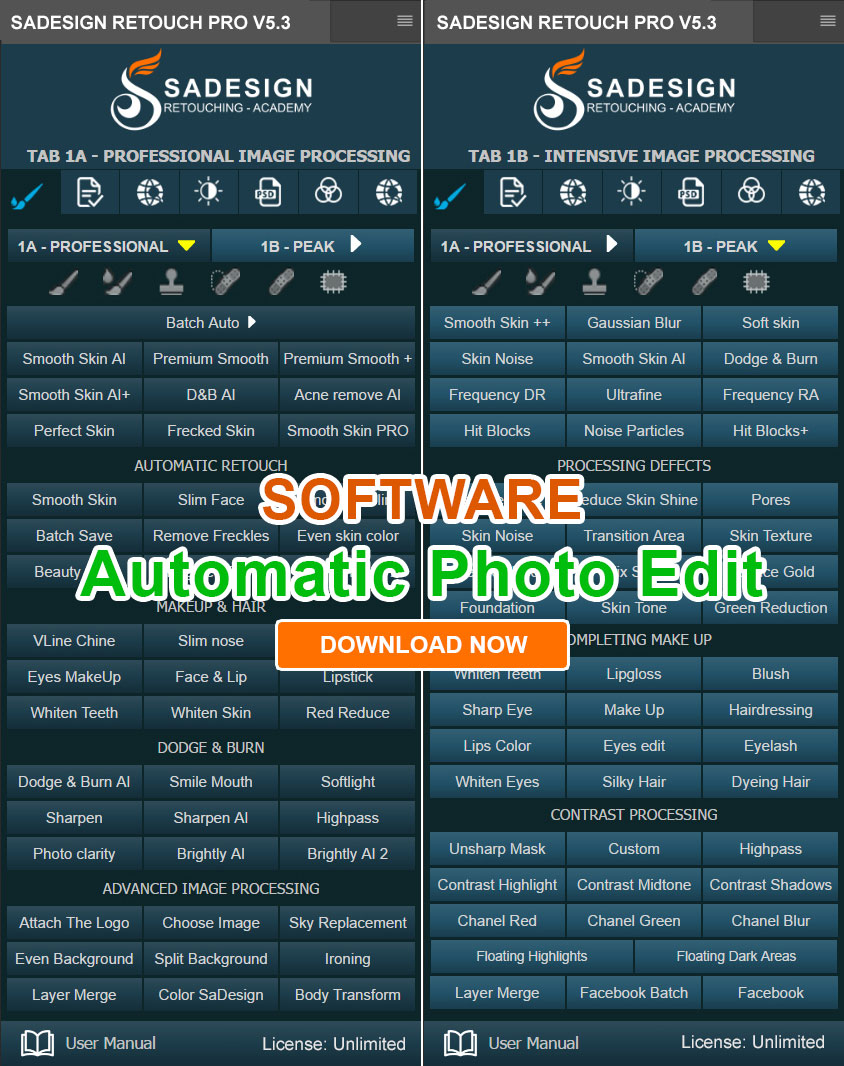

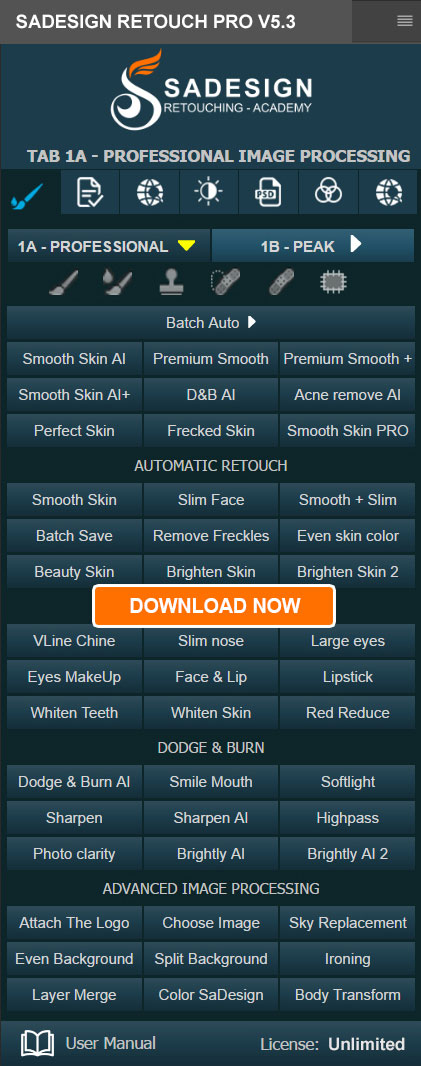

3. Tools and utilities to support design

3.1 Sketching Tools

Fusion 360 offers a flexible set of sketching tools that allow users to easily create basic shapes and complex curves. This not only makes design more intuitive, but also supports editing of dimensions and positions after the sketch is completed. This provides maximum flexibility, allowing users to adjust details quickly and efficiently.

With the sketch tool, users can apply geometric constraints to control the relationships between objects, thereby creating accurate and consistent drawings. This feature not only saves time but also reduces the possibility of errors during the design process.

3.2 Parametric Design

The parametric design tools in Fusion 360 allow users to quickly change the size and shape of parts, thanks to the ability to record every change in the timeline. This makes it easy for users to go back to previous steps to make necessary edits without worrying about losing important parameters.

With parametric design, creating product variations is easier than ever. Users can experiment with different sizes and shapes without having to start from scratch, increasing efficiency and accuracy in the design process.

3.3 CAM (Computer-Aided Manufacturing) machining tools

Fusion 360 integrates powerful CAM features that support machining processes such as milling, turning, and laser cutting. This allows users to convert 3D designs into CNC machine control code, optimizing machining time and accuracy. This feature not only saves effort but also minimizes risks in the manufacturing process.

Users can easily create accurate tool paths, adjust machining parameters, and preview results before execution. This brings high reliability and efficiency to the manufacturing process, thereby improving the quality of the final product.

3.4 Simulation and Analysis

Simulation features in Fusion 360 allow users to test the strength, durability, and performance of products under various operating conditions. Simulation tools such as stress, vibration, and temperature analysis help users assess weaknesses and improve designs before actual manufacturing.

Using simulation saves time and money by detecting problems early, thereby reducing risks in the product development process. Users can be more confident when bringing products to market, thanks to deep and detailed analysis.

(1).png)

3.5 Data Import and Export

Fusion 360 supports import and export of many popular file formats such as IGES, STEP, STL, and OBJ, optimizing data exchange with other CAD/CAM software. This feature allows users to easily integrate Fusion 360 into their existing workflow without any obstacles.

High compatibility with different file formats makes it easy for users to share projects and collaborate with colleagues or partners. This not only saves time but also improves team work efficiency.

3.6 Rendering tools

Rendering in Fusion 360 allows you to create high-quality images of your 3D designs. Users can customize lighting, materials, and environments to create realistic, lifelike images. This is useful not only for presenting products to customers, but also for evaluating and improving their designs.

With its impressive rendering capabilities, Fusion 360 helps users create professional, attention-grabbing visuals that make a strong impression in meetings or presentations. This not only enhances the value of the product but also contributes to the success of the sales process.

.png)

4. Fusion 360 Beginner's Guide

Installation and Account Registration : Start by downloading Fusion 360 from the Autodesk website. Once installed, you'll need to create an Autodesk account to activate the software and access its full features.

Learn the Interface : Fusion 360's interface is designed to be user-friendly, with tools clearly arranged. Take the time to familiarize yourself with each section of the interface to easily access features.

Explore sketching tools : Fusion 360 has a variety of powerful sketching tools. Try using tools like Line, Circle, and Rectangle to create basic shapes, then explore advanced tools like Offset, Fillet, and Chamfer to add detail and refine your design.

Create 3D models : Once you've completed your sketches, use tools like Extrude, Revolve, and Loft to transform your 2D shapes into living 3D models. This helps you visualize your design more visually.

Learn the basics of timeline : The timeline is an important feature that helps you track and edit steps in the design process. You can go back to change previous operations, which is extremely useful in editing and optimizing the design.

Don't forget to save and publish your design : Fusion 360 allows you to save your work online, making it easy to share your design with others. Make sure you publish your design in different formats, like STL, to prepare it for 3D printing or use in other applications.

(1).png)

5. Where should I upgrade Autodesk Fusion 360?

If you are looking for a reliable address to upgrade Autodesk Fusion 360, Sadesign is the perfect choice. With a cheap Fusion 360 license package of only 499,000 VND for 1 year of use, Sadesign brings you a comprehensive integrated design and engineering platform. This software not only provides powerful tools for 3D design but also supports analysis and production, helping to optimize your workflow.

Sadesign is committed to providing genuine products, lifetime warranty and dedicated installation support. In particular, you will be refunded 100% if you are not satisfied with the service. With a friendly interface and cloud collaboration features, Sadesign's Fusion 360 will help you increase design efficiency and improve product quality. Experience top-quality service at Sadesign today!

6. Conclusion

Autodesk Fusion 360 is a powerful tool for those working in the design and manufacturing industry. With the ability to integrate many functions from 3D design to simulation and manufacturing, this software not only helps users optimize their workflow but also opens up many creative opportunities. Whether you are a professional engineer or a beginner designer, Fusion 360 provides the necessary tools to realize your ideas efficiently and accurately. Explore Fusion 360 today to improve your design skills and expand your creativity!